Hazop and Risk Assessment and Management in Industries.

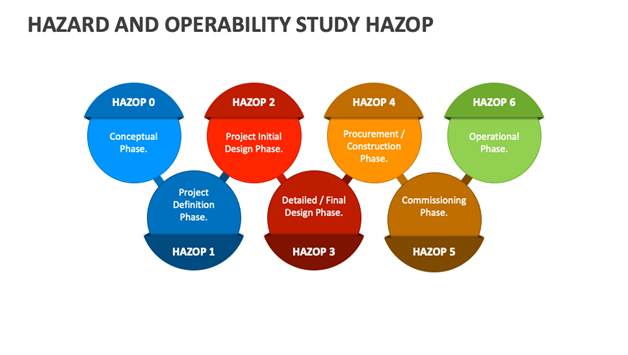

HAZOP is a structured and systematic examination of complex placement of process or operation to identify and evaluate problems that may represent risk to personnel or equipment. Intention of preparing is to review the design to pick up design or or otherwise engineering issues that otherwise have not been formed. The technique is based on overall complex design within a number of simple sections called nodes which are then individually reviewed. It is carried out by a multidisciplinary team (HAZOP) during a series of meetings. The HAZOP technique is quantitative and I am too stimulate the stimulate the inspiration of the participants to identify the potential hazards And operating problems, structure direction are given to the review process by applying standard guide words prompts to review Of each node. The relevant international standard calls for team members to display instruction and good judgement and for the meetings to be held interior climate of positive thinking and frank discussion Used in nuclear power plant, software development and batch operations.

Objectives Of Hazop Study

HAZOP in the process industry may be focused either to the assessment of safety (with a consideration of possible risk for both equipment and operators) or the operating(with regard to keeping of the required quantity of the product)

- Possibility of deceleration/ decomposition of raw materials.

- possibility of a failure of human factors..

- possibly of an exothermic reaction.

Advantages Of Hazop

- Systematic and Thorough examination of the assist equipment with an aim.

- Possibility to evacuate the consequences of a failure of the personnel with an aim to study dangerous situations.

- Finding of new Dangerous situations systematic procedure allowing to find new to dangerous situations that may occur.

- Increase the efficiency of the operation equipment finding of situations that may lead to towards disturbing of the operation I planned breaks damage of the equipment, laws of UN unprocessed raw but also towards improvement of the operational regulations

- Better understanding of the process, even experienced members of the process of the meeting acknowledge a new dimension new Information recording the operation of the assessed equipment.

Risk Management It And Assessment

Risk management can be defined as the collection of culture, process structures that are directed towards realizing potential opportunities while managing adverse effects. It can be defined as a systematic application of Management policies, procedures and practices. The risk management also incorporates several other tasks such as identifying, analyzing, evaluating and monitoring risk ok and reviewing risk.

Risk assessment is carried out on the use of methods, tools and risk assessment schemes. This or an unlimited number of strengths and weaknesses the approach and method of recording the results, analysis in Fault trees, Even trees and in spreadsheets. Even trees and in spreadsheets.

The schemes of risk analysis in trees are focused on a determined chain of events. While the spreadsheet methods are true to address the full scope of risk assessment(identification, analysis and evaluation)

The hazards and operability studies qualitative methods developed to identify risks and operating problems through the effects of deviations from design condition in industrial process place plants.

Qualitative Risk Analysis

The method with qualitative risk analysis is also based on the principle of brainstorming for creative development scenarios and finding the cases of deviations to identify safety functions.

Hazop Study For Quantitative Risk

databases. HAZOP technique is grounded by word application (such as more or less) to each process variable(temperature, flow, pressure). On the other hand PHA risks allows the definition of the rich position to prioritize the use of frequency and severity categories as a risk value.

Quantitative Approach Of HAZOP :

Aim is for integration with the risk of matrix. Because of this method east use the HAZOP and diagnosis method).

Parameters, guide word and deviation for each node).

From that, causes of consequences related to deviation are investigated.

From the HAZOP spreadsheet

Guide word/ deviation/ cause/ consequence.

PHA tool.

Frequency/ Severity/ Risk/ mitigation.

By V. Narasimhan, Chief consultant- Safety, NARASIMHAANS Safety